Oil & Natural Gas Heating and Industrial Processing

The Fitch® Fuel Catalyst:

Installed on almost 1,000 commercial, condo and Co-Op buildings in NYC

modifies fuel oil & natural gas extracting more energy per gallon

commercial applications have demonstrated a 3% - 15% reduction in fuel usage (Results vary with type of fuel)

residential oil applications recorded up to 20% reduction in fuel usage

commercial oil & natural gas applications ROI Typically within 6 - 12 months

residential oil applications ROI within 2 - 4 years depending on size of boiler/furnace

years of financial benefits

reduces soot and emission - improving indoor air quality (IAQ)

Substantially Reduces maintenance costs and unscheduled downtime of oil boiler or furnace

Installed easily within the fuel supply pipeline and is maintenance free

The Fitch Fuel Catalyst for oil use is UL certified, and installation does not affect the original equipment manufacturer’s warranty. Because fuel treated by the Fitch Fuel Catalyst burns more efficiently, carbon deposits are reduced, lowering maintenance requirements for the system. Installation in the fuel line is straightforward.

A qualified licensed professional should carry out the installation of a Fitch Fuel Catalyst on an oil or natural gas commercial or residential boiler, furnace or oven. The catalyst operates as a maintenance‑free device over its service life. In natural gas commercial systems, the Fitch unit must be sized based on the mass fuel flow rate at the Fitch installation location, rather than the equipment’s overall consumption rating. For sizing guidance or technical questions, contact your authorized distributor or APSI for assistance. _____________________________________________________________________

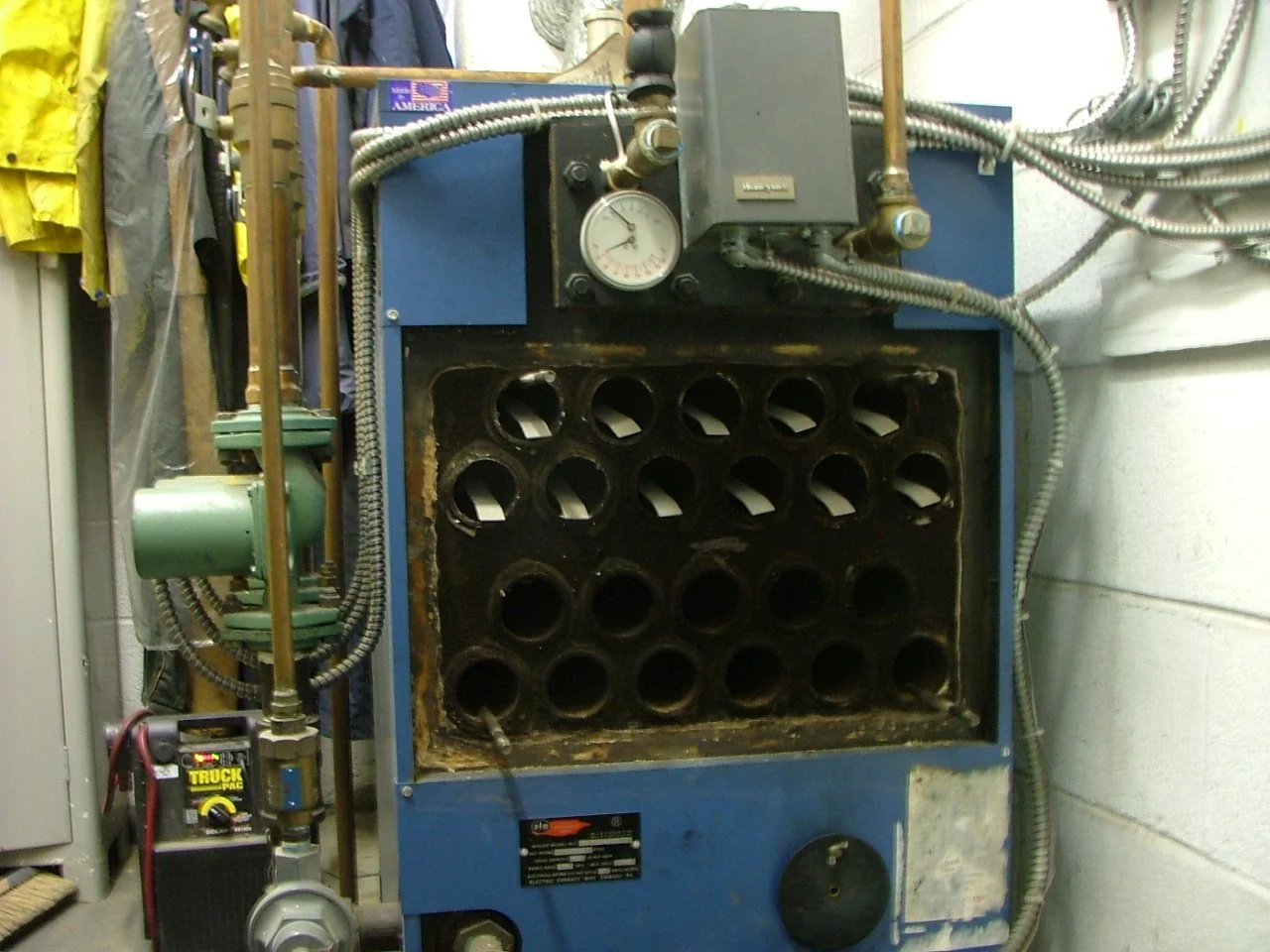

Without Fitch Fuel Catalyst After 6 months of Operation with Fitch Fuel Catalyst

Residential Oil Application

The Fitch Fuel Catalyst is a well-respected product which significantly reduces fuel oil expense and pollution. Their product is also cost-effective since the cost of the product can be returned in one fueling season without added expense or assessment.”

- Walter T. Gorman, P.E. – President – Walter T. Gorman, Inc. P.E., P.C. Consulting

Installed on almost 1,000 residential and commercial buildings in NYC

"Fitch was one of our best operational decisions ever. We reduced fuel consumption on our boiler by 10.4% and the Fitch Fuel Catalyst has more than paid for itself in less than one year."

- Nicholas Nikic: Resident Manager of 1088 Park Ave – a Douglas Elliman property

_____________________________________________________________________

“Amazing product! We installed the Fitch Fuel Catalyst in 2010 and within that first year, we saved just short of $15,000, recouped the cost of the unit, the cost of the installation, and put additional money back in our pocket. Best of all, the savings has been at least that much or more, year after year, at no additional cost."

- Brian Moore, Resident Manager 1115 Fifth Avenue - A Brown Harris Stevens property

_____________________________________________________________________

Applications: 4 Natural Gas Boilers producing steam for family-owned canning business - processing for beans, soups, gravies, sauces and broths

Fitch Models: 4 – FHD10NG Fitch natural gas in-line units

Results Reported by Customer: Improved the boilers’ combustion efficiency, reduced fuel consumption, and reduce overall operational costs.

__________________________________________________________________

"Jeffrey Gural, the chairman of Newmark Grubb Knight Frank, gave the converter a test run on a sample of the firm’s properties during the winter of 2011 and after a successful trial, made plans to outfit all of the firm’s oil‐heated properties by 2014. Oil that is treated via a Fitch Fuel Catalyst burns more efficiently and thus, carbon build‐up is reduced. This reduces the frequency of heating system cleanings as well as the emissions of greenhouse gases."

- Real Estate Weekly Sept 3, 2014, Dan Orlando

______________________________________________________________________

- Aluminum Smelting Furnace – Manufactured by Applied Foundry Solutions Rated at 21000000 BTU (6.1 MW)

Results: 15% less fuel used at high burn after Fitch was installed while maintaining the same heat output for production.

_____________________________________________________________________

To Whom it May Concern,

A Fitch Fuel Catalyst was installed on a residential oil burner in 2012 as part of a UConn Department of Chemistry project demonstration.

After installation, the burner and chimney stayed noticeably cleaner and required less frequent cleaning.

The nozzle was reduced from 0.65 gph to 0.5 gph (about a 24% reduction in firing rate), cutting estimated annual oil use from roughly 440 to 340 gallons and saving about $275 per year in fuel.

Over 11 years, the homeowner estimates saving roughly $1,100 in cleaning costs and $2,000–$2,500 in fuel, while also reducing emissions from oil combustion.

After 11 years of positive financial and environmental results, the homeowner is purchasing a new Fitch Fuel Catalyst and strongly recommends it for residential and commercial fuel‑oil or natural‑gas systems.

Best Regards,

Mr. Dave Wells

Shrewsbury, MA

2/7/2024